Electroplated Diamond Mandrels

Electroplated Diamond Mandrels – Precision ID Grinding & Finishing | Braemar USA

Electroplated Diamond Mandrels are engineered for high-accuracy internal grinding, polishing, and shaping of the toughest materials used in optics, ceramics, carbide tooling, sapphire, quartz, and advanced technical manufacturing. Each mandrel is manufactured using premium synthetic diamond, precision electroplating, and tight geometric tolerances—ensuring fast cutting action, long tool life, and exceptional dimensional accuracy in small-diameter internal work.

Designed for ID grinding, bore polishing, radius generation, slotting, and high-precision finishing, these mandrels deliver consistent performance on both CNC and manual grinding equipment.

High-Performance Electroplated Construction

Braemar’s electroplated diamond technology provides:

-

Single-layer, sharp diamond exposure for aggressive cutting

-

Excellent form accuracy—ideal for precision internal geometry

-

Cool cutting due to open-structure plating

-

Minimal loading and consistent chip evacuation

-

Superior edge-holding for tight-tolerance grinding

Electroplated mandrels are ideal for applications requiring free-cutting action, minimal heat generation, and high material-removal efficiency.

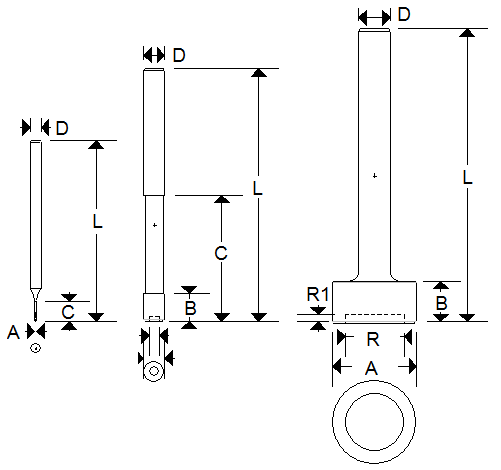

Mandrel Styles & Diameters

Braemar USA manufactures a full range of mandrel styles:

-

Straight mandrels

-

Taper mandrels

-

Radius and form mandrels

-

Micro-diameter mandrels for small bores

-

Custom geometries for optical and semiconductor work

Available in diameters from 0.5 mm to 12 mm (custom sizes available).

Materials These Mandrels Grind

Electroplated diamond mandrels are optimized for:

-

Sapphire

-

Quartz

-

Ceramics (alumina, zirconia, machinable ceramics)

-

Carbide

-

Hardened steels

-

Optical glass

-

Silicon carbide & advanced materials

Applications

Perfect for high-precision internal work such as:

-

ID grinding and bore sizing

-

Optical lens and prism finishing

-

Radius generation

-

Slot grinding

-

Chamfering & deburring

-

Micro-finishing in semiconductor and medical components

Why Choose Braemar USA Electroplated Diamond Mandrels?

-

Industry-leading precision plating

-

Consistent diamond exposure across the entire abrasive surface

-

Long-life mandrels with exceptional form stability

-

Custom engineering for CNC, optical, and advanced machining systems

-

Fast delivery and U.S.-based technical support

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

ITEM

DM015

DM020

DM025

DM030

DM040

DM050

DM060

DM080

DM100

DM120

DM140

DM160

DM180

DM200

DM235

DM250

DM275

DM335

DM375

DM500

DM625

DM750

DM1000

A

0.015

0.020

0.025

0.030

0.040

0.050

0.060

0.080

0.100

0.120

0.140

0.160

0.180

0.200

0.235

0.250

0.275

0.335

0.375

0.500

0.625

0.750

1.000

B

0.100

0.100

0.100

0.100

0.100

0.100

0.125

0.150

0.150

0.150

0.200

0.200

0.235

0.235

0.275

0.275

0.300

0.300

0.300

0.400

0.400

0.500

0.500

C

0.187

0.187

0.187

0.250

0.250

0.250

0.500

0.500

0.500

0.500

0.625

N/A

N/A

1.000

1.000

1.000

N/A

N/A

N/A

N/A

N/A

N/A

N/A

D

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.250

0.250

0.250

0.250

0.250

0.250

0.375

0.375

0.375

0.375

L

2.150

2.150

2.150

2.150

2.150

2.150

2.150

2.150

2.150

2.150

2.150

2.150

2.150

3.000

3.000

3.000

3.000

3.000

3.000

3.000

3.000

3.500

3.500

R

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

0.125

0.125

0.200

0.200

0.250

0.350

0.400

0.700

R1

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

0.040

0.040

0.040

0.040

0.050

0.050

0.050

0.100

GRIT

200/230

200/230

200/230

200/230

200/230

200/230

200/230

200/230

200/230

200/230

200/230

200/230

100/120

100/120

100/120

100/120

100/120

100/120

100/120

100/120

100/120

100/120

100/120

ITEM:

DM015

A:

0.015

B:

0.100

C :

0.187

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM020

A:

0.020

B:

0.100

C :

0.187

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM025

A:

0.025

B:

0.100

C :

0.187

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM030

A:

0.030

B:

0.100

C :

0.250

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM040

A:

0.040

B:

0.100

C :

0.250

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM050

A:

0.050

B:

0.100

C :

0.250

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM060

A:

0.060

B:

0.125

C :

0.500

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM080

A:

0.080

B:

0.150

C :

0.500

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM100

A:

0.100

B:

0.150

C :

0.500

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM120

A:

0.120

B:

0.150

C :

0.500

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM140

A:

0.140

B:

0.200

C :

0.625

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM160

A:

0.160

B:

0.200

C :

N/A

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

200/230

ITEM:

DM180

A:

0.180

B:

0.235

C :

N/A

D:

0.125

L:

2.150

R:

N/A

R1:

N/A

GRIT:

100/120

ITEM:

DM200

A:

0.200

B:

0.235

C :

1.000

D:

0.250

L:

3.000

R:

N/A

R1:

N/A

GRIT:

100/120

ITEM:

DM235

A:

0.235

B:

0.275

C :

1.000

D:

0.250

L:

3.000

R:

N/A

R1:

N/A

GRIT:

100/120

ITEM:

DM250

A:

0.250

B:

0.275

C :

1.000

D:

0.250

L:

3.000

R:

0.125

R1:

0.040

GRIT:

100/120

ITEM:

DM275

A:

0.275

B:

0.300

C :

N/A

D:

0.250

L:

3.000

R:

0.125

R1:

0.040

GRIT:

100/120

ITEM:

DM335

A:

0.335

B:

0.300

C :

N/A

D:

0.250

L:

3.000

R:

0.200

R1:

0.040

GRIT:

100/120

ITEM:

DM375

A:

0.375

B:

0.300

C :

N/A

D:

0.250

L:

3.000

R:

0.200

R1:

0.040

GRIT:

100/120

ITEM:

DM500

A:

0.500

B:

0.400

C :

N/A

D:

0.375

L:

3.000

R:

0.250

R1:

0.050

GRIT:

100/120

ITEM:

DM625

A:

0.625

B:

0.400

C :

N/A

D:

0.375

L:

3.000

R:

0.350

R1:

0.050

GRIT:

100/120

ITEM:

DM750

A:

0.750

B:

0.500

C :

N/A

D:

0.375

L:

3.500

R:

0.400

R1:

0.050

GRIT:

100/120

ITEM:

DM1000

A:

1.000

B:

0.500

C :

N/A

D:

0.375

L:

3.500

R:

0.700

R1:

0.100

GRIT:

100/120

ITEM:

A:

B:

C :

D:

L:

R:

R1:

GRIT: