Electroplated Diamond Chamfer Tools

Electroplated Diamond Chamfer Tools and Diamond Chamfer Cones are high-precision edge-conditioning instruments engineered for machining hard, brittle, and wear-resistant materials. Manufactured using a controlled nickel electroplating process, these tools incorporate a single, uniform layer of synthetic diamond particles metallurgically bonded to a rigid steel or carbide substrate. This plating method ensures maximum exposure of each abrasive crystal, producing exceptionally sharp cutting edges capable of generating accurate chamfers, bevels, and conical edge geometries with minimal heat and minimal subsurface damage.

Electroplated Bond Structure

The electroplated bond system uses a nickel matrix that permanently anchors each diamond grain in a fixed position. Because the abrasive layer is non-renewable, the exposed diamond retains consistent geometry throughout the life of the tool, providing predictable cutting behavior. This configuration is ideal for chamfering, edge-breaking, deburring, and tapered-edge formation on materials where conventional abrasive bonds wear rapidly or generate excessive heat.

Diamond Chamfer Tools

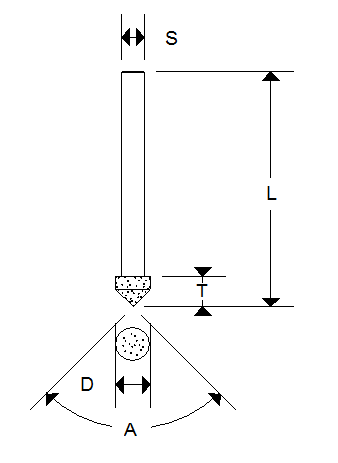

Straight-profile Electroplated Diamond Chamfer Tools (also referred to as plated diamond chamfer tools, diamond beveling cutters, and electroplated edge-shaping tools) are available in standardized included angles such as 60°, 82°, and 90°, with the ability to manufacture custom angles for specialized edge profiles. These tools are widely used in applications requiring controlled bevel geometry, tight dimensional tolerance, and uniform surface finish across optical, ceramic, and semiconductor components.

Diamond Chamfer Cones

Diamond Chamfer Cones—also called diamond cones, electroplated diamond cones, diamond conical chamfer tools, or plated cone bevel cutters—are specifically designed for producing precision tapered chamfers, conical countersinks, and angle-controlled reliefs. The conical geometry enables smooth material entry, stable cutting behavior, and predictable load distribution, making these tools essential for wafer edge prep, quartz tapering, sapphire cone formation, and high-accuracy cone-shaping in advanced engineering materials.

Applications Across Advanced Materials

Electroplated chamfer tools and cone cutters are optimized for machining:

-

Quartz, Fused Silica & Glass — chip-controlled beveling, tapering, and pre-polish edge formation

-

Sapphire & Optical Crystals — high-precision chamfers for optics, photonics, and micro-mechanical components

-

Technical Ceramics (Alumina, Zirconia, SiC) — stable edge profiles and low-damage cutting

-

Carbide, Hardened Steels & Tool Steels — chamfering, countersinking, and conical relief in tool-and-die applications

-

Semiconductor Wafers & Electronic Substrates — controlled conical bevels, micro-edge tapering, and substrate preparation

These materials benefit from electroplated diamond tooling due to its sharp cutting action, thermal stability, and extremely low risk of mechanical shock or uncontrolled fracture.

Performance Characteristics

-

High Cutting Efficiency: Exposed diamond grains maintain aggressive removal rates on ultra-hard substrates.

-

Thermal Stability: Electroplated layers generate significantly less heat than resin or metal bond systems.

-

Dimensional Precision: Geometry remains consistent across the tool’s life due to non-renewable abrasive structure.

-

Reduced Subsurface Damage: Minimal grinding force minimizes micro-cracking and preserves material integrity.

-

Rigid Support Body: Steel or carbide cores ensure vibration-free, repeatable machining.

-

Custom Manufacturing: Tools can be produced with variable diameters, lengths, cone angles, and diamond grit sizes.

Available Specifications

Braemar USA manufactures electroplated chamfer tools and diamond cones in diameters ranging from 0.060” to 3.000”, with custom tolerances, included angles, grit sizes, land widths, and shank configurations available for CNC, rotary, ultrasonic, and manual grinding systems.

This is a great alternative, Metal Bond Diamond Chamfer Tools

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

0036062

0054611

0100242

0054151

0106328

0193161

DPCHSS690A

0020881

0097241

0020883

0156362

0156361

0110475

0110478

0188702

--------------

0106321

0073431

0106322

0005586

DPCHSS640A

0179121

0156361

0143161

--------------

DPCHSS730A

DPCHSS780A

DPCHSS815A

DPCHSS940A

DPCHSS991

DPCHSS995

--------------

DPCHSS400A

DPCHSS400B

DPCHSS400C

DPCHSS420A

DPCHSS420B

0049873

0133331

0133332

--------------

0112881

0112887

0112890

0134011

--------------

0156363

DPCHSS750A

(D) DIAMETER

0.250

0.300

0.360

0.375

0.500

0.625

0.640

0.680

0.750

0.750

1.000

1.150

1.575

1.575

2.000

.....................

0.500

0.500

0.500

0.577

0.640

0.750

1.000

2.500

.....................

0.730

0.780

0.815

0.940

1.173

1.650

.....................

0.400

0.400

0.400

0.420

0.420

0.575

3.000

3.000

.....................

0.196

0.196

0.196

0.250

.....................

1.000

0.750

(T) HEIGHT

0.130

0.130

0.330

0.250

0.500

0.375

0.350

0.300

0.275

0.375

0.500

0.350

0.828

0.828

1.000

.....................

0.500

0.500

0.500

0.500

0.565

0.750

0.500

1.250

.....................

0.350

0.330

0.330

0.270

0.265

0.400

.....................

0.200

0.200

0.500

0.400

0.400

0.325

0.750

0.750

.....................

1.120

1.120

1.120

0.890

.....................

0.300

0.350

(S) SHANK

0.125

0.500

0.250

0.250

0.250

0.125

0.250

0.500

0.750

0.375

0.250

0.500

0.750

0.750

0.375

.....................

0.250

0.500

0.250

0.500

0.187

0.500

0.250

0.750

.....................

0.236

0.250

0.250

0.250

0.500

0.500

.....................

0.187

0.187

0.187

0.187

0.187

0.500

0.750

0.750

.....................

0.750

0.750

0.750

0.750

.....................

0.500

0.250

(L) LENGTH

2.000

2.500

1.830

2.000

3.000

1.500

2.000

3.000

3.275

3.000

3.000

2.500

3.328

3.328

2.000

.....................

3.000

3.000

3.000

3.000

2.000

2.500

3.000

4.000

.....................

2.000

2.000

2.000

2.000

2.000

2.000

.....................

2.000

2.000

1.135

2.000

2.000

2.850

4.000

4.000

.....................

4.540

4.540

4.540

5.250

.....................

3.000

1.900

(A) ANGLE

90°

90°

90°

90°

90°

90°

90°

90°

90°

90°

90°

90°

90°

90°

90°

.....................

60°

60°

60°

60°

60°

60°

60°

60°

.....................

82°

82°

82°

82°

82°

82°

.....................

45°

45°

45°

45°

45°

45°

45°

45°

.....................

16°

16°

16°

16°

.....................

120°

59°

(G) GRIT

100/120

300/325

200/230

100/120

100/120

170/200

080/100

140/170

200/230

140/170

200/230

140/170

140/170

270/300

120/140

.....................

200/235

140/170

100/120

200/230

080/100

200/230

200/230

200/230

.....................

080/100

080/100

080/100

100/120

100/120

100/120

.....................

080/100

100/120

080/100

080/100

080/100

170/200

400

400

.....................

600

600

400

600

.....................

200/230

080/100

:

0036062

(D) DIAMETER:

0.250

(T) HEIGHT:

0.130

(S) SHANK:

0.125

(L) LENGTH:

2.000

(A) ANGLE:

90°

(G) GRIT:

100/120

:

0054611

(D) DIAMETER:

0.300

(T) HEIGHT:

0.130

(S) SHANK:

0.500

(L) LENGTH:

2.500

(A) ANGLE:

90°

(G) GRIT:

300/325

:

0100242

(D) DIAMETER:

0.360

(T) HEIGHT:

0.330

(S) SHANK:

0.250

(L) LENGTH:

1.830

(A) ANGLE:

90°

(G) GRIT:

200/230

:

0054151

(D) DIAMETER:

0.375

(T) HEIGHT:

0.250

(S) SHANK:

0.250

(L) LENGTH:

2.000

(A) ANGLE:

90°

(G) GRIT:

100/120

:

0106328

(D) DIAMETER:

0.500

(T) HEIGHT:

0.500

(S) SHANK:

0.250

(L) LENGTH:

3.000

(A) ANGLE:

90°

(G) GRIT:

100/120

:

0193161

(D) DIAMETER:

0.625

(T) HEIGHT:

0.375

(S) SHANK:

0.125

(L) LENGTH:

1.500

(A) ANGLE:

90°

(G) GRIT:

170/200

:

DPCHSS690A

(D) DIAMETER:

0.640

(T) HEIGHT:

0.350

(S) SHANK:

0.250

(L) LENGTH:

2.000

(A) ANGLE:

90°

(G) GRIT:

080/100

:

0020881

(D) DIAMETER:

0.680

(T) HEIGHT:

0.300

(S) SHANK:

0.500

(L) LENGTH:

3.000

(A) ANGLE:

90°

(G) GRIT:

140/170

:

0097241

(D) DIAMETER:

0.750

(T) HEIGHT:

0.275

(S) SHANK:

0.750

(L) LENGTH:

3.275

(A) ANGLE:

90°

(G) GRIT:

200/230

:

0020883

(D) DIAMETER:

0.750

(T) HEIGHT:

0.375

(S) SHANK:

0.375

(L) LENGTH:

3.000

(A) ANGLE:

90°

(G) GRIT:

140/170

:

0156362

(D) DIAMETER:

1.000

(T) HEIGHT:

0.500

(S) SHANK:

0.250

(L) LENGTH:

3.000

(A) ANGLE:

90°

(G) GRIT:

200/230

:

0156361

(D) DIAMETER:

1.150

(T) HEIGHT:

0.350

(S) SHANK:

0.500

(L) LENGTH:

2.500

(A) ANGLE:

90°

(G) GRIT:

140/170

:

0110475

(D) DIAMETER:

1.575

(T) HEIGHT:

0.828

(S) SHANK:

0.750

(L) LENGTH:

3.328

(A) ANGLE:

90°

(G) GRIT:

140/170

:

0110478

(D) DIAMETER:

1.575

(T) HEIGHT:

0.828

(S) SHANK:

0.750

(L) LENGTH:

3.328

(A) ANGLE:

90°

(G) GRIT:

270/300

:

0188702

(D) DIAMETER:

2.000

(T) HEIGHT:

1.000

(S) SHANK:

0.375

(L) LENGTH:

2.000

(A) ANGLE:

90°

(G) GRIT:

120/140

:

--------------

(D) DIAMETER:

.....................

(T) HEIGHT:

.....................

(S) SHANK:

.....................

(L) LENGTH:

.....................

(A) ANGLE:

.....................

(G) GRIT:

.....................

:

0106321

(D) DIAMETER:

0.500

(T) HEIGHT:

0.500

(S) SHANK:

0.250

(L) LENGTH:

3.000

(A) ANGLE:

60°

(G) GRIT:

200/235

:

0073431

(D) DIAMETER:

0.500

(T) HEIGHT:

0.500

(S) SHANK:

0.500

(L) LENGTH:

3.000

(A) ANGLE:

60°

(G) GRIT:

140/170

:

0106322

(D) DIAMETER:

0.500

(T) HEIGHT:

0.500

(S) SHANK:

0.250

(L) LENGTH:

3.000

(A) ANGLE:

60°

(G) GRIT:

100/120

:

0005586

(D) DIAMETER:

0.577

(T) HEIGHT:

0.500

(S) SHANK:

0.500

(L) LENGTH:

3.000

(A) ANGLE:

60°

(G) GRIT:

200/230

:

DPCHSS640A

(D) DIAMETER:

0.640

(T) HEIGHT:

0.565

(S) SHANK:

0.187

(L) LENGTH:

2.000

(A) ANGLE:

60°

(G) GRIT:

080/100

:

0179121

(D) DIAMETER:

0.750

(T) HEIGHT:

0.750

(S) SHANK:

0.500

(L) LENGTH:

2.500

(A) ANGLE:

60°

(G) GRIT:

200/230

:

0156361

(D) DIAMETER:

1.000

(T) HEIGHT:

0.500

(S) SHANK:

0.250

(L) LENGTH:

3.000

(A) ANGLE:

60°

(G) GRIT:

200/230

:

0143161

(D) DIAMETER:

2.500

(T) HEIGHT:

1.250

(S) SHANK:

0.750

(L) LENGTH:

4.000

(A) ANGLE:

60°

(G) GRIT:

200/230

:

--------------

(D) DIAMETER:

.....................

(T) HEIGHT:

.....................

(S) SHANK:

.....................

(L) LENGTH:

.....................

(A) ANGLE:

.....................

(G) GRIT:

.....................

:

DPCHSS730A

(D) DIAMETER:

0.730

(T) HEIGHT:

0.350

(S) SHANK:

0.236

(L) LENGTH:

2.000

(A) ANGLE:

82°

(G) GRIT:

080/100

:

DPCHSS780A

(D) DIAMETER:

0.780

(T) HEIGHT:

0.330

(S) SHANK:

0.250

(L) LENGTH:

2.000

(A) ANGLE:

82°

(G) GRIT:

080/100

:

DPCHSS815A

(D) DIAMETER:

0.815

(T) HEIGHT:

0.330

(S) SHANK:

0.250

(L) LENGTH:

2.000

(A) ANGLE:

82°

(G) GRIT:

080/100

:

DPCHSS940A

(D) DIAMETER:

0.940

(T) HEIGHT:

0.270

(S) SHANK:

0.250

(L) LENGTH:

2.000

(A) ANGLE:

82°

(G) GRIT:

100/120

:

DPCHSS991

(D) DIAMETER:

1.173

(T) HEIGHT:

0.265

(S) SHANK:

0.500

(L) LENGTH:

2.000

(A) ANGLE:

82°

(G) GRIT:

100/120

:

DPCHSS995

(D) DIAMETER:

1.650

(T) HEIGHT:

0.400

(S) SHANK:

0.500

(L) LENGTH:

2.000

(A) ANGLE:

82°

(G) GRIT:

100/120

:

--------------

(D) DIAMETER:

.....................

(T) HEIGHT:

.....................

(S) SHANK:

.....................

(L) LENGTH:

.....................

(A) ANGLE:

.....................

(G) GRIT:

.....................

:

DPCHSS400A

(D) DIAMETER:

0.400

(T) HEIGHT:

0.200

(S) SHANK:

0.187

(L) LENGTH:

2.000

(A) ANGLE:

45°

(G) GRIT:

080/100

:

DPCHSS400B

(D) DIAMETER:

0.400

(T) HEIGHT:

0.200

(S) SHANK:

0.187

(L) LENGTH:

2.000

(A) ANGLE:

45°

(G) GRIT:

100/120

:

DPCHSS400C

(D) DIAMETER:

0.400

(T) HEIGHT:

0.500

(S) SHANK:

0.187

(L) LENGTH:

1.135

(A) ANGLE:

45°

(G) GRIT:

080/100

:

DPCHSS420A

(D) DIAMETER:

0.420

(T) HEIGHT:

0.400

(S) SHANK:

0.187

(L) LENGTH:

2.000

(A) ANGLE:

45°

(G) GRIT:

080/100

:

DPCHSS420B

(D) DIAMETER:

0.420

(T) HEIGHT:

0.400

(S) SHANK:

0.187

(L) LENGTH:

2.000

(A) ANGLE:

45°

(G) GRIT:

080/100

:

0049873

(D) DIAMETER:

0.575

(T) HEIGHT:

0.325

(S) SHANK:

0.500

(L) LENGTH:

2.850

(A) ANGLE:

45°

(G) GRIT:

170/200

:

0133331

(D) DIAMETER:

3.000

(T) HEIGHT:

0.750

(S) SHANK:

0.750

(L) LENGTH:

4.000

(A) ANGLE:

45°

(G) GRIT:

400

:

0133332

(D) DIAMETER:

3.000

(T) HEIGHT:

0.750

(S) SHANK:

0.750

(L) LENGTH:

4.000

(A) ANGLE:

45°

(G) GRIT:

400

:

--------------

(D) DIAMETER:

.....................

(T) HEIGHT:

.....................

(S) SHANK:

.....................

(L) LENGTH:

.....................

(A) ANGLE:

.....................

(G) GRIT:

.....................

:

0112881

(D) DIAMETER:

0.196

(T) HEIGHT:

1.120

(S) SHANK:

0.750

(L) LENGTH:

4.540

(A) ANGLE:

16°

(G) GRIT:

600

:

0112887

(D) DIAMETER:

0.196

(T) HEIGHT:

1.120

(S) SHANK:

0.750

(L) LENGTH:

4.540

(A) ANGLE:

16°

(G) GRIT:

600

:

0112890

(D) DIAMETER:

0.196

(T) HEIGHT:

1.120

(S) SHANK:

0.750

(L) LENGTH:

4.540

(A) ANGLE:

16°

(G) GRIT:

400

:

0134011

(D) DIAMETER:

0.250

(T) HEIGHT:

0.890

(S) SHANK:

0.750

(L) LENGTH:

5.250

(A) ANGLE:

16°

(G) GRIT:

600

:

--------------

(D) DIAMETER:

.....................

(T) HEIGHT:

.....................

(S) SHANK:

.....................

(L) LENGTH:

.....................

(A) ANGLE:

.....................

(G) GRIT:

.....................

:

0156363

(D) DIAMETER:

1.000

(T) HEIGHT:

0.300

(S) SHANK:

0.500

(L) LENGTH:

3.000

(A) ANGLE:

120°

(G) GRIT:

200/230

:

DPCHSS750A

(D) DIAMETER:

0.750

(T) HEIGHT:

0.350

(S) SHANK:

0.250

(L) LENGTH:

1.900

(A) ANGLE:

59°

(G) GRIT:

080/100