9A3 Diamond Wheels

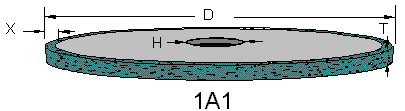

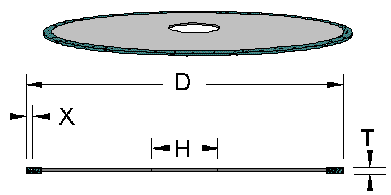

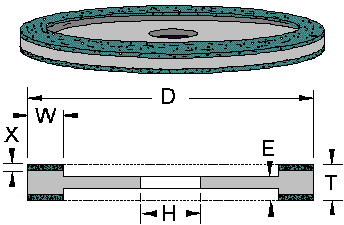

Overview and Wheel Design

9A3 Diamond Wheels from Braemar USA are built for high-accuracy grinding where steady geometry and clean surfaces matter. The 9A3 shape uses a flared cup design with a strong, reinforced rim. This stronger rim helps the wheel stay stiff during heavy cuts and hold its shape through long grinding cycles. As a result, the wheel makes controlled contact with carbide tools, ceramics, and other brittle materials.

Grinding Access and Stability

The 9A3 profile gives good access to edges, flutes, and complex shapes. Because the wheel offers wide approach angles, it reduces interference while grinding. Its low runout and balanced core also cut down vibration and force changes. Therefore, the cutting zone stays stable, surface quality improves, and micro-chipping drops. These gains help when working on carbide, alumina, sapphire, quartz, and other technical materials.

Bond Options for Better Performance

Resin Bond

The resin bond runs cool and breaks down in a controlled way. This creates a self-sharpening effect that keeps the wheel cutting freely. It also reduces heat, which protects carbide and ceramic parts. For that reason, resin wheels work well for fluting, sharpening, and fine finishing.

Metal Bond

Metal bonds keep their form under high pressure. They resist wear and stay stable during tough grinding. Because of this, they suit hard and brittle optical materials like fused silica, sapphire, and dense ceramics.

Electroplated Bond

Electroplated wheels use a single diamond layer with high exposure. This gives a sharp, free-cutting action with very low force. As a result, they are ideal for slots, small features, and work that needs instant cutting without dressing.

Performance in Advanced Manufacturing

Across toolmaking, optics, ceramics, and semiconductor work, the 9A3 wheel produces clean flutes, sharp edges, and smooth surfaces. Since the shape stays stable, fine details remain intact and repeatability improves. Setup time drops, tool life grows, and quality stays consistent. With strong diamond, tight tolerances, and well-matched bond choices, Braemar USA’s 9A3 wheels deliver steady results in demanding shops.

SDDD Alternative Truing Method

Truing Stick for Diamond & CBN Resin Bond Wheels

“A new simple way”

more information on our SDDD Truing Stick

.

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

(D) DIAMETER

6.000"

6.000"

7.000"

10.000"

12.000"

14.000"

(T) WHEEL WIDTH

0.750"

1.000"

0.750"

0.750"

0.750"

0.750"

(H) ARBOR HOLE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

(W) RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

(D) DIAMETER:

6.000"

(T) WHEEL WIDTH:

0.750"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH

GRIT SIZE:

SPECIFY GRIT SIZE

(D) DIAMETER:

6.000"

(T) WHEEL WIDTH:

1.000"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH

GRIT SIZE:

SPECIFY GRIT SIZE

(D) DIAMETER:

7.000"

(T) WHEEL WIDTH:

0.750"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH

GRIT SIZE:

SPECIFY GRIT SIZE

(D) DIAMETER:

10.000"

(T) WHEEL WIDTH:

0.750"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH

GRIT SIZE:

SPECIFY GRIT SIZE

(D) DIAMETER:

12.000"

(T) WHEEL WIDTH:

0.750"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH

GRIT SIZE:

SPECIFY GRIT SIZE

(D) DIAMETER:

14.000"

(T) WHEEL WIDTH:

0.750"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH

GRIT SIZE:

SPECIFY GRIT SIZE